- HMPP winding storage tank production line

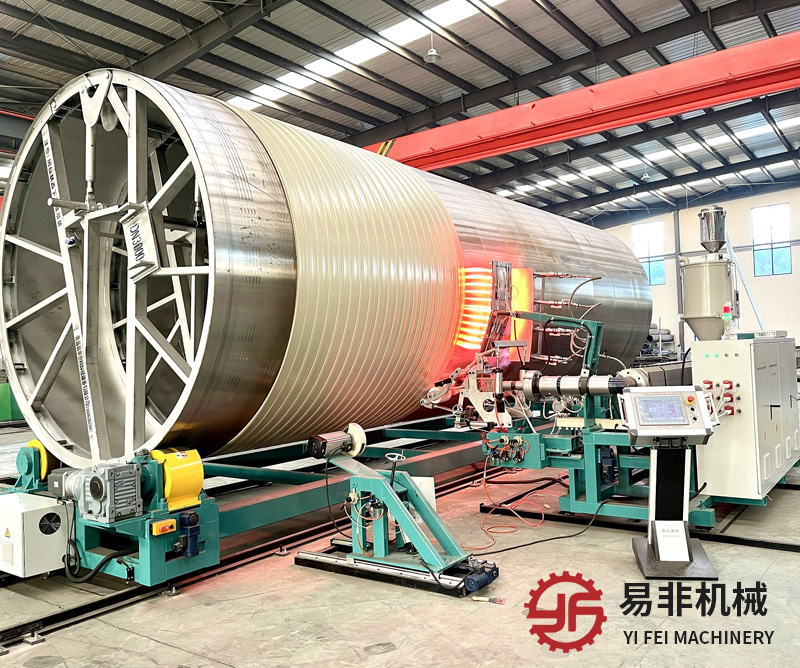

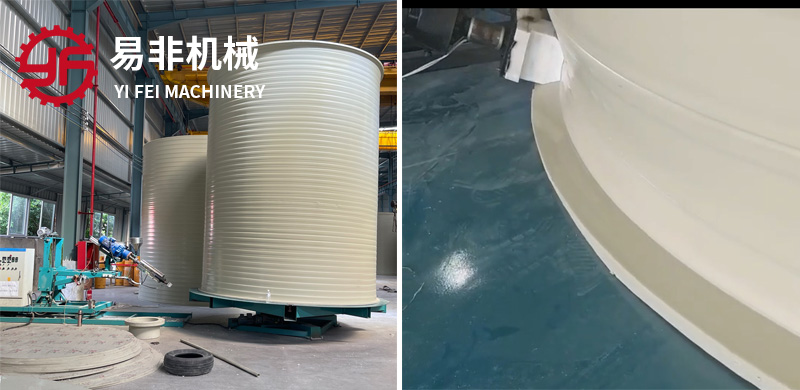

- PPH winding storage tank production line

- PP PE Plastic Welding Rod Production Line

- Plastic sheet production line

- PPH winding can mold

- PP vertebral body round head winding equipment

- Plastic sheet welding machine

- Plastic sheet bending machine

- Plastic sheet welding and bending integrated machine

- Plastic board carving machine

- Square internal and external welding automatic extrusion welding machine

- Automatic extrusion welding machine for inner and outer welding of round cans

- Plastic extrusion welding gun

- Plastic tank punching and cutting machine

The forming process of the dual station PPH winding tank production line adopts two high-efficiency screw co extrusion winding composite forming technologies. Greatly increased production capacity. The winding thickness of PPH wrapped storage tanks can reach over 60mm, and the tank body of the wrapped tank adopts a seamless design to avoid the risk of leakage. It can be used in environments above atmospheric pressure. The product is widely used in industries such as new energy storage, chemical, dye, pesticide, metallurgy, rare earth, machinery, power, electronics, environmental protection, textile, brewing, food, water supply, and drainage.

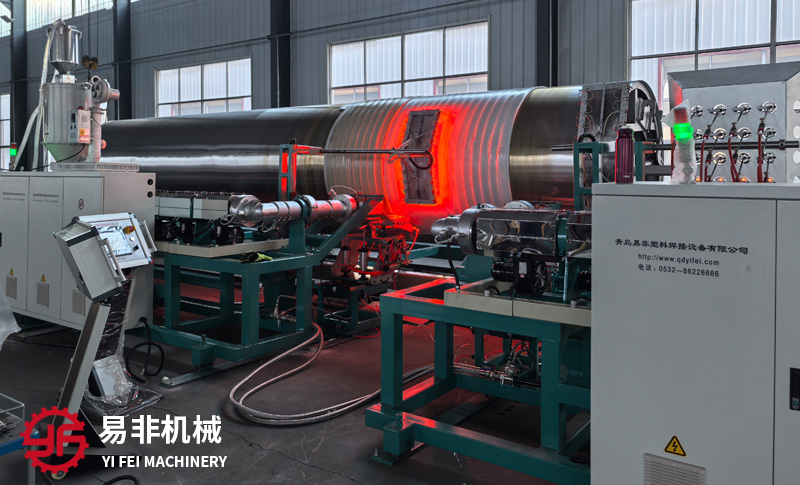

2、 Disc Extrusion Automatic Welding Machine (External Vertical Welding Production)

3、 Long arm extrusion automatic welding machine (internal horizontal welding production)

PPH/HDPE winding storage tanks are mainly used in equipment in the following industries: (1) In the new energy industry, they are mainly used for electrolyte storage and vertical storage tanks required for various production processes. (2) In the anti-corrosion and environmental protection industry, it is mainly used to produce equipment such as spray towers, transfer tanks, mixing tanks, reaction tanks, etc. for waste gas treatment. (3) In the chemical and pharmaceutical industry, it is mainly used in vertical storage tanks, measuring tanks, pickling tanks, quartz sand storage tanks, etc. (4) In the sewage treatment industry, it can be used to manufacture HMPP integrated pumping stations, horizontal storage tanks, etc.